To rear a pig for bacon, sausages or pork chops, takes eight months. That’s eight months of feed, water and antibiotics, not to mention the space dedicated to industrial farming and the energy and resources needed to rear thousands of animals.

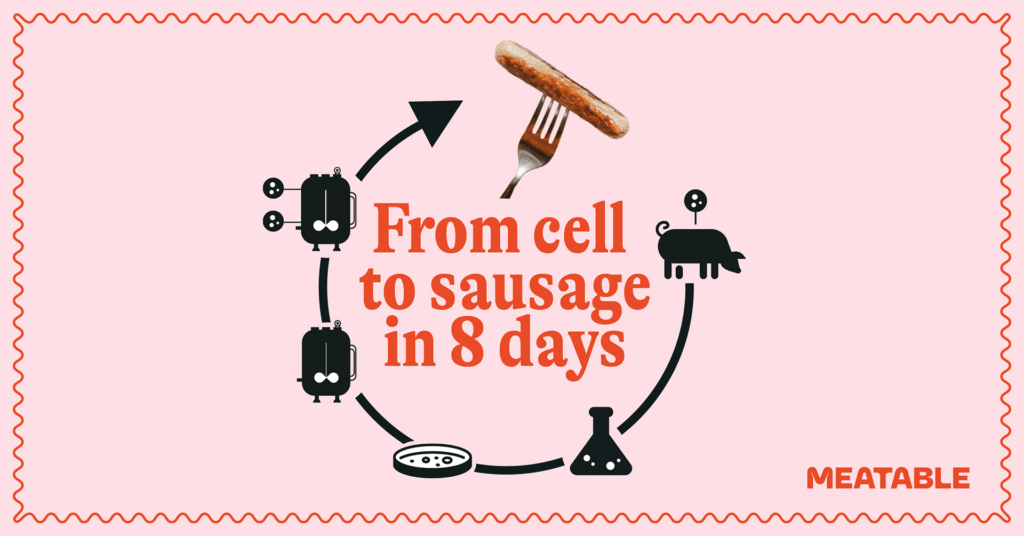

At Meatable, we’ve just hit a major milestone. We can now create delicious, tasty cultivated pork sausages in only eight days – less than 5% of the time needed to rear a pig on a farm.

This is truly a groundbreaking moment for us as a team. Early research showed it was possible to create cultivated meat back in 2013. But this was at an astronomical price, which would have been very difficult to scale unless everyone in the world was a billionaire. Not to mention this was still using animal sources, which went against our principles as founders and as a company.

Since we started Meatable in 2018, we have been working towards our mission to create delicious cultivated meat products without harming people, animals or the planet. Over the past year, we have made real progress in developing a process that is efficient, scaleable, and produces products only of the highest quality. Today, we are proud to say we have reached this major milestone.

Meat is delicious, but its cost is too much

We like to eat meat because it tastes good, holds cultural and religious significance, and provides the nutrients many people need for a balanced diet. It’s also readily available, thanks to the conventional meat industry with its optimised production processes, mature supply chain and infrastructure and de-risked technology that all make meat cheap and abundant. It’s so successful that global meat production has more than tripled in the last 60 years and it’s on track to grow further – from 350 billion kg annually to between 460 to 570 billion kg by 2050.

But all this comes at a huge cost. Animal agriculture is the largest cause of deforestation globally and contributes 14% of all greenhouse gas emissions. Around 70% of antibiotics globally are for industrial livestock farming and 25% of all human diseases have agricultural starting points. On top of that, the demand for meat continues to grow as the population nears 10 billion people, so we need to find a sustainable solution.

The solution: cultivated meat

We believe cultivated meat is the fundamental solution to solve the negative impact meat has on the planet. It doesn’t require large-scale dietary changes, it provides the same nutrients and taste as conventional meat and it relies on scientifically proven techniques which have long been used in the pharmaceutical industry. Whilst it is still early days, we’re excited by the developments we’ve made to create high-quality cultivated meat that looks and tastes like conventional meat.

To create Meatable’s cultivated meat, our team first isolates a single animal cell, taken harmlessly from an animal. While immortalised cell lines are more commonly found in the industry, they require an alteration of the cells to allow them to multiply indefinitely. Our technology is instead based on pluripotent stem cells (PSCs), which have the natural ability to keep on multiplying and to do so rapidly. In our process, we have a doubling time of only 24 hours. Meanwhile, the difficulty with using PSCs is that it can be more challenging to change them from stem cells into more specialised cells, such as muscle or fat. However, by using these cells in combination with our patented opti-ox™ technology, we’re able to produce real muscle and fat cells that are fully differentiated in just days.

This is coupled with a perfusion process that allows the team to work in a continuous cycle to generate very high cell densities. We’ve been able to reach 80 million cells per millilitre and are pushing this even further. (If you’re not a scientist, this means we can grow a lot of cells in our bioreactors, and harvest cultured meat from the reactors continuously. This is a great step forward as it increases productivity and makes the process easy to scale).

The multiplying and differentiation of our cells occur in bioreactors filled with nutrients needed to feed the cells (also called media). To optimise the process and decrease costs, we will scale to bioreactors of 50m3. As well, we have been able to reduce our media costs for some of these nutrients by 100x, in part thanks to a joint research project with Royal DSM. This is also why the speed element of our process is so important – it drives down the number of reactors required, the amount of media we need, as well as labour and energy, which all makes it more affordable, easier to scale and reduces the impact of meat on the environment.

Altogether, this means that when it comes to making real cultivated meat, we have the tools to make the process extremely efficient and one that can scale to serve customers around the world.

The same taste and texture as conventional meat, without guilt

We have been investing time and research into creating the most efficient process for cultivated meat possible, all without compromising on taste, texture and quality. Our cultivated meat cells are indistinguishable from traditional muscle and fat cells. As well, by using PSCs in our process, we can fully differentiate our cells, which allows us to create the right level of fibre formation, protein and fat accumulation in the cells which is similar to those in traditional pork. This gives meat its pronounced flavour and bite so that when someone tries a Meatable cultivated pork sausage or dumpling, or even delicious pulled pork, salami and pork belly, they are enjoying the same taste, texture and nutritional value of conventional meat, without the guilt associated.

Now we have proven we can produce our cultivated pork sausages in just eight days, hitting a major milestone in developing a process that is efficient, scalable, and produces products only of the highest quality. We will keep on working towards our mission to create delicious cultivated meat products without harming people, animals or the planet. This is critical for our mission to save 27 million animal lives by 2035.